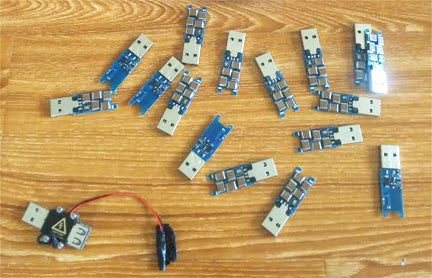

Before the PCBs leave the factory, they are visually inspected, and also inspected for continuity problems in a testing jig. When all circuits pass, they are dispatched.

Once we receive them, we also do a manual test on each PCB - so that we can guarantee our products are 100% functional.

Testing is done using our very own USB Killer 2.0 Testing Shield! Each USB Killer is plugged in - we check the LED lights (indicating a good charge) - we short the data line breakout on the testing shield; we're looking for a good spark, and rapid charge from the USB Killer.

Once the tests are passed, the entire lot is dispatched to the factory that assembles the final housing: USB cases, aluminium case, and cardboard boxes.

All the products are boxed, bar-coded, packed, and delivered to the warehouse for dispatch to our customers.

If you're waiting on your USB Killer to come off back-order - it will be from this batch that your order is sent. We're still on target for September 14 for the next shipments to be sent.

For those of you that have received your USB Killers - please let us know your results.

We're aiming to build a database of vulnerable hardware.

Anything else - please contact us - we'd love to hear from you.

Leave a comment: